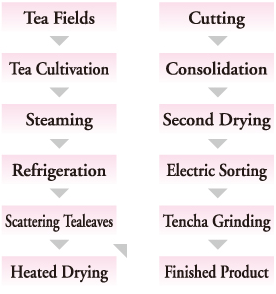

At the beginning of May, we start picking Sencha leaves, and about two weeks later we begin to harvest Gyokuro and Tencha (the tea leaves used to make Maccha). The first harvest of the year, which is called “New Tea” (or “ First Flush Tea”) is said to have the highest quality of aroma and flavor. For later harvests, our production methods combine the best technologies with a human touch to bring out the true potential of each tea variety.

In the past, all of the grinding was done by hand

Tea Mortars of the Taisho Period (1912-1926)

Completely Dried tea leaves

After passing through the cleaning room, on the way to the Maccha factory

A Present Day Maccha Factory

So what do you think of traditional tea practices? Today, Shohokuen’s factories have the most sophisticated machinery available for tea manufacture. But our tea manufacturer's spirit has remained the same as that of our pioneer family 350 years ago. We are sensitive in dealing with Mother Nature and are grateful for the gifts she brings us. That is why we do not use any food additives or chemicals and strive to exclusively make products that are good for our health.